What Level of First Aid does your Company Require?

It’s simple, Employers in BC are responsible to provide first aid in the workplace. Hire a first aider, or train an existing employee to carry out first aid duties, buy some equipment, and you’re done right? But what about those instances where the workplace is remote, or work sites where there are dozens or even hundreds of employees?

One of our mobile treatment centers with an experienced level 3 first aid attendant standing by to ensure the safely of this work-crew.

In these instances you may be required to bolster your levels of first aid to be in compliance with the Occupational Health and Safety Regulations.

To determine levels of first aid coverage, the employer must conduct a first aid assessment. First aid coverage depends on the total workforce present at each workplace and the hazard rating given to your type of work. Hazard ratings can be determined in the table found in part 3.16 of the BC Occupational Health and Safety Guidelines.

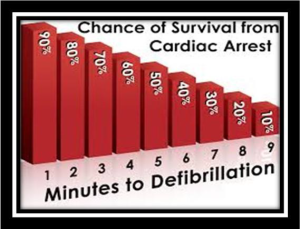

The number of workers and hazard rating are just two of the pieces you need to determine your first aid coverage requirements. The third piece is your work site’s surface travel time to hospital. After all, the survival of an injured worker depends greatly upon how quickly your first aid attendant can respond and how soon you can transport the patient to medical aid if required.

As you conduct your first aid assessment you may find that you are required to have emergency vehicles and equipment at your work site. This is where OH&S Safety Consulting and Training Solutions LTD. can help. We have fully stocked mobile treatment centers, Emergency transportation vehicles, and industrial ambulances to assist you in meeting your first aid requirements. We also provide qualified, competent, first aiders and industrial paramedics for the duration of your project.

Our mobile treatment centers and first aid attendants are always ready for your project big or small

If your first aid assessment finds that your workplace is required to have a level 3 first aider and a mobile treatment center, phone OH&S Safety Consulting and Training Solutions LTD. and ask us how we can help!

778-471-6407